Mon, Jul 17, 2017

AD NUMBER: 2017-10-12

PRODUCT: Airbus Helicopters Model AS332C, AS332C1, AS332L, AS332L1, AS332L2, and EC225LP helicopters.

ACTION: Final Rule.

SUMMARY: This AD requires repetitive inspections of the intermediate gear box (IGB) fairing. This AD was prompted by separation of the IGB fairing from the fairing gutter and subsequent interference with the drive shaft.

These helicopters have been approved by the aviation authority of France and are approved for operation in the United States. Pursuant to our bilateral agreement with France, EASA, its technical representative, has notified us of the unsafe condition described in the EASA AD.

The FAA is issuing this AD because we evaluated all information provided by EASA and determined the unsafe condition exists and is likely to exist or develop on other helicopters of these same type designs and that air safety and the public interest require adopting the AD requirements as proposed.

The FAA estimates that this AD affects 11 helicopters of U.S. Registry and that labor costs average $85 per work-hour. Based on these estimates, we expect the following costs:

- Visually inspecting each IGB fairing and the left- and right-hand attachment supports for a crack require a 0.5 work-hour for a total cost of $43 per helicopter and $473 for the U.S. fleet, per inspection cycle.

- Replacing the IGB fairing requires 2 work hours and parts cost $2,600, for a total cost of $2,770 per helicopter and $30,470 for the U.S. fleet.

- Replacing the attachment supports requires 2 work hours, and parts cost $1,100 for a total cost of $1,270 per helicopter.

- Visually inspecting for a crack in the fairing gutter requires 0.5 work hour for a total cost of about $43 per helicopter.

- Inspecting for interference and separation of the fairing gutter requires 0.5 work hour for a total cost of $43 per helicopter.

- Replacing the inclined drive shaft tube requires 2 work hours, and parts cost $18,399, for a total cost of $18,569 per helicopter.

- Replacing a hydraulic pipe requires 2 work hours, and parts cost $1,322, for a total cost of $1,492 per helicopter.

- Repairing the flight control assembly requires 2 work hours, and parts cost $484, for a total cost of $654 per helicopter.

DATES: This AD is effective August 15, 2017.

FMI: AD

More News

Aero Linx: JAARS Nearly 1.5 billion people, using more than 5,500 languages, do not have a full Bible in their first language. Many of these people live in the most remote parts of>[...]

'Airplane Bounced Twice On The Grass Runway, Resulting In The Nose Wheel Separating From The Airplane...' Analysis: The pilot reported, “upon touchdown, the plane jumped back>[...]

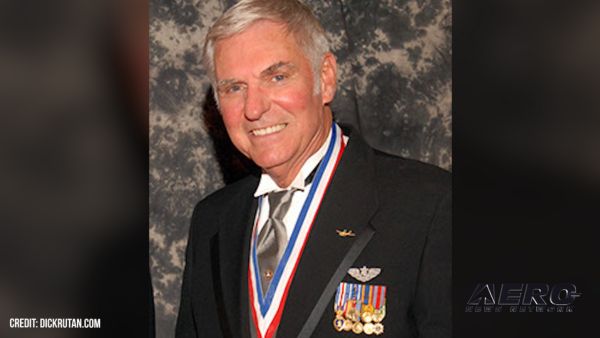

"Burt is best known to the public for his historic designs of SpaceShipOne, Voyager, and GlobalFlyer, but for EAA members and aviation aficionados, his unique concepts began more t>[...]

"Polaris Dawn, the first of the program’s three human spaceflight missions, is targeted to launch to orbit no earlier than summer 2024. During the five-day mission, the crew >[...]

There Are SO Many Ways To Get YOUR Aero-News! It’s been a while since we have reminded everyone about all the ways we offer your daily dose of aviation news on-the-go...so he>[...]

ANN's Daily Aero-Linx (05.04.24)

ANN's Daily Aero-Linx (05.04.24) NTSB Final Report: Quest Aircraft Co Inc Kodiak 100

NTSB Final Report: Quest Aircraft Co Inc Kodiak 100 Aero-News: Quote of the Day (05.04.24)

Aero-News: Quote of the Day (05.04.24) Aero-News: Quote of the Day (05.05.24)

Aero-News: Quote of the Day (05.05.24) Read/Watch/Listen... ANN Does It All

Read/Watch/Listen... ANN Does It All