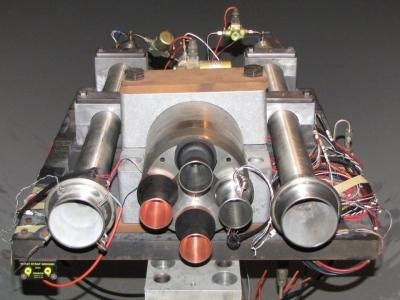

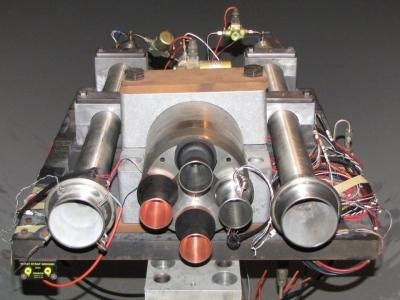

Two Percent Scale Models Being Used For Hotfire Tests

To better understand the heating conditions at the base of what will be the biggest, most powerful rocket ever built, engineers at NASA's Marshall Space Flight Center in Huntsville, AL, are thinking small -- really small.

Models of NASA's Space Launch System (SLS) core stage RS-25 engines and solid rocket boosters -- scaled down to just 2 percent of the actual size of the flight hardware -- have been designed, built and hot-fire tested at sea level conditions. The tests are part of the Pathfinder Test Program, which is run by Marshall engineers in close collaboration with Calspan-University of Buffalo Research Center Inc., in Buffalo, N.Y. The SLS core stage, towering more than 200 feet tall with a diameter of 27.6 feet, will store the cryogenic liquid hydrogen and liquid oxygen that will feed the vehicle’s RS-25 engines.

The replicas will help engineers in a huge way by providing data on the convective heating environments that the base of the vehicle will experience during ascent. The models were developed for base heating testing scheduled for this summer.

Data from those tests will be used to set specifications for the design of the rocket's base thermal protection system, which keeps major hardware such as wiring, and later the crew, safe from the extreme heat the boosters and engines create while burning on ascent.

So why use mini rocket engines?

"Using scale models of the SLS core stage engines and boosters are not only cost-effective but also can fit in a wind tunnel," said Manish Mehta, lead engineer for the SLS Base Heating Test Program. "Wind tunnel testing is one of the most proven ways to adequately simulate the pressure and heating an actual rocket will experience during ascent. We had to make sure these models achieve aerodynamic and rocket plume similarity with the real flight vehicle as close as possible."

Base heating test models date back to the Saturn and Space Shuttle programs. However, the last major hot fire model design effort for a NASA launch vehicle was for the shuttle in the late 1970s.

“This type of testing is not business as usual," said Mark Seaford, a Marshall engineer who works on the test project. "We had to go back and review the old shuttle model drawings and design rules of thumb as a starting point. Young engineers on our team took those past practices and came up with innovative approaches to designing and testing these models."

"It was really exciting to see the energy generated by this team and getting the opportunity to do something dynamic and challenging," Seaford added.

Mehta said some of those challenges were to develop the engines and motors for short-duration testing -- with test-run times around 150 milliseconds. The team also used new engineering materials and design tools, including computational fluid dynamics -- numerical codes used to predict internal flow behavior in the engine.

"Without computational fluid dynamics, we'd be blind," Mehta said. "The codes were extremely crucial on determining the design of these rocket engine models. Our team numerically investigated several different design iterations, until all performance requirements were satisfied for a final design."

"We also had the opportunity to use high-speed, high-resolution visible and infrared cameras -- technology that wasn't available on past programs," Mehta added. "The visible video camera alone -- almost 500 times faster than a regular camera -- was integral in verifying the design and similarity to the actual flight plumes."

The models, which took about a year and a half to design and build to flight specifications and performance, were fabricated and tested at Calspan-University of Buffalo Research Center Inc. A 2-percent scale model of the entire SLS, about 6.5-feet long, is currently being designed at that facility ahead of the final complete vehicle base heating test this summer.

The first flight test of the SLS in 2017 will feature a configuration for a 70-metric-ton (77-ton) lift capacity and carry an uncrewed Orion spacecraft beyond low-Earth orbit to test the performance of the integrated system. As the SLS evolves, it will provide an unprecedented lift capability of 130-metric-tons (143 tons) to enable missions even farther into our solar system to places such as an asteroid and ultimately Mars.

(Images provided by NASA)

ANN's Daily Aero-Term (04.26.24): DETRESFA (Distress Phrase)

ANN's Daily Aero-Term (04.26.24): DETRESFA (Distress Phrase) ANN's Daily Aero-Linx (04.26.24)

ANN's Daily Aero-Linx (04.26.24) Airborne 04.22.24: Rotor X Worsens, Airport Fees 4 FNB?, USMC Drone Pilot

Airborne 04.22.24: Rotor X Worsens, Airport Fees 4 FNB?, USMC Drone Pilot Airborne 04.24.24: INTEGRAL E, Elixir USA, M700 RVSM

Airborne 04.24.24: INTEGRAL E, Elixir USA, M700 RVSM Airborne-NextGen 04.23.24: UAVOS UVH 170, magni650 Engine, World eVTOL Directory

Airborne-NextGen 04.23.24: UAVOS UVH 170, magni650 Engine, World eVTOL Directory