Mon, May 02, 2005

Propellers - Variable Pitch - Hamilton Standard

AD/PHS/18 Amdt 2 Hub Cracking 6/2005

Applicability:

All model 14RF-9, 14RF-19 and 14RF-21 propellers.

Note 1: These propellers may be installed on but are not limited to

Embraer EMB-120 series, CASA CN-235 series and SAAB SF-340 series

aircraft.

Requirement: 1. (a) Perform a torque check of

the propeller hub retaining nuts, in accordance with the applicable

Hamilton Sundstrand Maintenance Manual (MM).

(b) Remove from service propellers where the hub retaining nuts are

found not to meet the acceptance criteria outlined in the

applicable Hamilton Sundstrand MM.

(c) Inspect for cracks in accordance with the applicable Hamilton

Sundstrand MM.

(d) Remove from service propeller hubs with cracks.

(e) If the propeller hub retaining nut torque check is acceptable

in accordance with the applicable Hamilton Sundstrand MM, support

the propeller with an appropriate lifting fixture and loosen the

propeller hub retaining nuts. Tighten the propeller hub retaining

nuts as detailed in the applicable Hamilton Sundstrand MM.

(f) Make an entry in the propeller maintenance records to

record:

(i) that the initial torque check was performed;

(ii) the propeller hub retaining nuts were loosened and tightened

in accordance with Requirement 1(e) of this Directive; and

(iii) the torque values.

2. Repeat requirement 1 of this Directive.

3. Install all propellers using the propeller hub retaining nut

tightening procedure defined in the applicable Hamilton Sundstrand

MM. Record the torque values in accordance with Requirement 1(d) of

this Directive.

4. (a) Visually inspect for and investigate all external propeller

oil leakage.

(b) If the leakage is found to be caused by other than a leak in

the blade seal, the pressure relief valve, or actuator assembly,

remove the propeller from service.

Note 2: FAA AD 94-06-05 Amdt 39-8853 refers.

Compliance: 1

(a) Unless previously accomplished in accordance with the original

issue or

amendment 1 of this Directive, within 30 days from the effective

date of this Directive.

(b) Before further flight.

(c) Unless previously accomplished in accordance with the original

issue or amendment 1 of this Directive, within 30 days from the

effective date of this Directive.

(d) Before further flight.

(e) Following requirement 1(a) of this Directive and prior to

further flight.

(f) Following completion of Requirement 1(a) and 1(e) of this

Directive.

2. At intervals not to exceed 500 flight hours.

3. From the effective date of this Directive.

4. (a) At intervals not to exceed 85 flight hours.

(b) Before further flight.

This Amendment becomes effective on 9 June 2005.

Background: The original issue of this

Directive addressed manufacturer’s torqueing procedures for

the propeller hub retaining nuts, which was insufficient to prevent

fretting during normal propeller operation. If allowed to continue,

cracking of the propeller hub may occur.

This amendment corrects errors in Amendment 1 of the Directive

with no change to

the intent of the Directive. Amendment 1 removed references to

manufacturer’s temporary revision and instead refers to the

manufacturers publications that incorporate the correct values and

procedures for torqueing the propeller hub retaining nuts.

Amendment 1 of this Directive became effective 27 November 2003.

The original issue of this Directive became effective 4 May

1994.

More News

Omnidirectional Approach Lighting System ODALS consists of seven omnidirectional flashing lights located in the approach area of a nonprecision runway. Five lights are located on t>[...]

"Polaris Dawn, the first of the program’s three human spaceflight missions, is targeted to launch to orbit no earlier than summer 2024. During the five-day mission, the crew >[...]

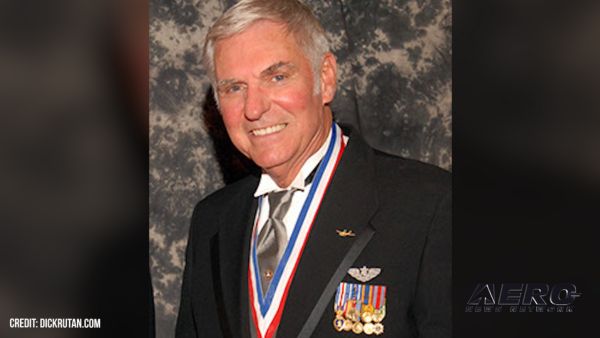

Also: 1800th E-Jet, Uncle Sam Sues For Landing Gear, Embraer Ag Plane, Textron Parts A friend of the family reported that Lt. Col. (Ret.) Richard Glenn Rutan flew west on Friday, M>[...]

Also: Virgin Galactic, B-29 Doc to Allentown, Erickson Fire-Fighters Bought, FAA Reauthorization After dealing with a big letdown after the unexpected decision by Skyreach to disco>[...]

“Our aircrews are trained and capable of rapidly shifting from operational missions to humanitarian roles. We planned to demonstrate how we, and our BORSTAR partners, respond>[...]

ANN's Daily Aero-Term (05.05.24): Omnidirectional Approach Lighting System

ANN's Daily Aero-Term (05.05.24): Omnidirectional Approach Lighting System Aero-News: Quote of the Day (05.05.24)

Aero-News: Quote of the Day (05.05.24) Airborne 05.06.24: Gone West-Dick Rutan, ICON BK Update, SpaceX EVA Suit

Airborne 05.06.24: Gone West-Dick Rutan, ICON BK Update, SpaceX EVA Suit Airborne 05.03.24: Advanced Powerplant Solutions, PRA Runway Woes, Drone Racing

Airborne 05.03.24: Advanced Powerplant Solutions, PRA Runway Woes, Drone Racing Aero-News: Quote of the Day (05.06xx.24)

Aero-News: Quote of the Day (05.06xx.24)