Focuses On Failure Of Airmotive Engineering Corp. PMA Cylinder Assemblies

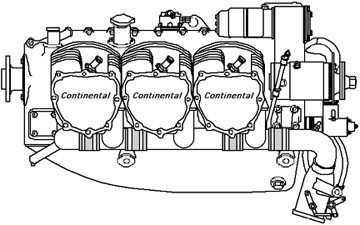

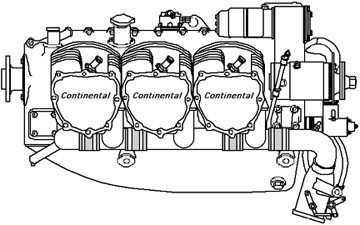

The FAA on Monday posted a notice in the Federal Register proposing an Airworthiness Directive for certain Airmotive Engineering Corp. replacement parts manufacturer approval (PMA) cylinder assemblies marketed by Engine Components International Division (ECi), used on the Continental Motors, Inc. (CMI) models 520 and 550 reciprocating engines, and all other engine models approved for the use of CMI models 520 and 550 cylinder assemblies such as the CMI model 470 when modified by supplemental type certificate (STC).

The proposed AD was prompted by failure reports of multiple cylinder head-to-barrel separations and cracked and leaking aluminum cylinder heads. This proposed AD would require initial and repetitive inspections, replacement of cracked cylinders, and replacement of cylinder assemblies at reduced times-in-service. This proposed AD would also prohibit the installation of affected cylinder assemblies into any engine. We are proposing this AD to prevent cylinder head cracks, engine failure, and loss of the airplane.

The proposed AD would require removing Group A cylinder assemblies from service within 25 operating hours if, on the effective date of the AD, the cylinder operating hours are fewer than 500 hours, or more than 1,000 hours. This proposed AD would also require removing Group B cylinder assemblies from service within 25 operating hours if, on the effective date of the AD, the cylinder operating hours are 1,000 or more.

It would also require repetitive visual inspections, compression tests, and leak checks for cracks, for Group A cylinder assemblies with between 500 and 1,000 operating hours, and for Group B cylinder assemblies with fewer than 1,000 operating hours, until they are removed from service.

Finally, this proposed AD would also prohibit installing affected ECi cylinder assemblies onto any engine and would require reporting to the FAA all removed cylinder assemblies.

The FAA estimates that the costs to properly inspect and repair the affected engines will total some $82.6 million. Comments must be received on the proposed AD by October 11th of this year.

ECi said in a news release that, in the company's view, the FAA’s proposed action will degrade safety, not improve it.

The proposed AD would limit the allowable time-in-service of more than 30,000 TITAN brand 520- and 550-series cylinder assemblies installed on about 6,000 Continental IO-520, TSIO-520, IO-550 and IOF-550 engines. The proposed AD affects a broad serial number range of cylinder assemblies (p/n AEC631397), and would require that these cylinders be removed from service at 1,000 hours time-in-service. The company says about half the affected cylinders would be required to be removed from service within 25 hours if their time-in-service is less than 500 hours. Cylinders permitted to continue in service would be subject to repetitive 50-hour inspections until they are retired.

Engine Components International (ECi) believes that the FAA’s proposed AD is unwarranted, inappropriate, and unnecessarily punitive for the owners of the affected aircraft. The FAA’s action was prompted by 30 instances (out of 30,000 installed) of head-to-barrel junction failures in TITAN cylinders, but none of these failures resulted in an accident or injury. Such failures result in a loss of 20% of engine power, leaving ample power to make a safe landing, which is exactly what happened in every case. In fact, FAA regulation requires that engines must be designed to operate safely with one cylinder not functioning. A substantial number of the failures occurred in twin-engine aircraft, where the safety consequences were even less significant. In fact, there have been more than 1,200 similar head-to-barrel failures in 520/550 cylinders manufactured by other Production Approval Holders for which the FAA has taken no action.

Airmotive Engineering Corp (AEC), sister company of ECi and the Production Approval Holder for the TITAN cylinder, provided the FAA with a detailed analysis of such failures from the FAA’s own Service Difficulty Report (SDR) database showing that the failure rate of TITAN cylinders is the lowest in the industry.

The FAA’s action arose out of a February 2012 safety recommendation by the NTSB (A-12-7). However, in a move that is almost unprecedented, the FAA’s proposed AD goes far beyond what the NTSB recommended. The NTSB’s recommendation was to remove the cylinders from service when they reached Continental’s recommended engine TBO (typically 1,600 to 2,200 hours), but the FAA is proposing to remove them from service at 1,000 hours, and in addition to remove a substantial number of under 500-hour cylinders immediately.

The company says that on February 14, 2013, top executives of AEC met with representatives of the FAA and NTSB to present results of extensive research performed by the company—including test-cell runs, torture testing of head-to-barrel junctions, and mathematical finite-element modeling—which demonstrated conclusively that the head-to-barrel junctions in these cylinders would not fail if the cylinder was operated within its design temperature limits. AEC explained to the FAA and NTSB that the few separations suffered were due to operation of the cylinders with CHTs well above the maximum allowable operating limit of 460°F. In some cases, the failures were caused by improper leaning and powerplant management by the pilot; in other cases, they were caused by abnormal combustion events such as heavy detonation and pre-ignition that can cause thermal runaway and rapidly increase CHT to temperatures of 650°F or more. No cylinder assembly from any manufacturer can survive such

temperatures for more than a few minutes.

There is no empirical or theoretical evidence that life-limiting the cylinders will reduce the incidence of head-to-barrel separations. To the contrary, industry experience demonstrates that the FAA’s proposed AD would actually degrade safety rather than improve it.

The FAA’s action would result in thousands of premature “top overhauls” where all six cylinders are removed and replaced in hundreds of general maintenance shops by A&P mechanics who are not engine specialists. Industry experience shows that there is a substantial risk of catastrophic engine failure following such top overhauls. All eight through-bolts that clamp the crankcase halves together are un-torqued, opening the door for main bearing displacement and other potentially catastrophic issues. In addition, the replacement cylinders are then broken in “in the field” rather than on the test stand in an engine shop, which often leads to improper break-in and excessive blow-by that can overheat and compromise the integrity of the head-to-barrel junction of the replaced cylinder.

ANN's Daily Aero-Term (04.24.24): Runway Lead-in Light System

ANN's Daily Aero-Term (04.24.24): Runway Lead-in Light System ANN's Daily Aero-Linx (04.24.24)

ANN's Daily Aero-Linx (04.24.24) Aero-FAQ: Dave Juwel's Aviation Marketing Stories -- ITBOA BNITBOB

Aero-FAQ: Dave Juwel's Aviation Marketing Stories -- ITBOA BNITBOB Classic Aero-TV: Best Seat in The House -- 'Inside' The AeroShell Aerobatic Team

Classic Aero-TV: Best Seat in The House -- 'Inside' The AeroShell Aerobatic Team Airborne Affordable Flyers 04.18.24: CarbonCub UL, Fisher, Affordable Flyer Expo

Airborne Affordable Flyers 04.18.24: CarbonCub UL, Fisher, Affordable Flyer Expo