Company Actively Supporting Replacement of Defective Parts

Oregon-based Van’s Aircraft is reviewing, testing, and finalizing a web portal by which customers in receipt of cracked aircraft parts may report such and arrange to take delivery of replacement components. In the interest of ensuring proper function, a number of Van’s customers have been invited to preliminarily assess the portal.

Information pertaining to the portal and instructions for accessing such will be sent to Van’s customers upon the testing-regimen’s conclusion.

Van’s set forth in a 15 September website posting: “Our engineering team is completing work on an update covering laser-cut parts testing, evaluation, and classification. This document will help explain the statuses assigned to parts with some detail about how various parts are evaluated and statuses are assigned. We will also soon post an update to the laser-cut parts list document, which will include the latest updated statuses.”

Customers visiting the portal will be presented lists of laser-cut parts from which they may specify the replacements they require. The portal will also afford Van’s customers opportunity to select non-laser-cut parts at no additional charge. Customers requiring replacements of punched parts will be able to request and view discounted prices for subject parts via the portal.

Van’s anticipates the scope and volume of parts requested by customers will allow the company to refine its production schedules for requested parts and determine shipping timeframes. Once part volumes and production and delivery timing are calculated (as functions of the number of replacement parts requested) Van’s asserts it will pass data pertaining to such along to its customers.

Additionally, Van’s—for purpose of collecting data and opinions germane to its aircraft kits—will presently disseminate a survey among the company’s Quick Build customers.

Van’s stated: “Our engineering team’s testing process continues and significant progress has been made to include additional fatigue tests, finite element analysis, and destructive load tests. We will communicate additional information about the testing next week.

In early 2022, Van’s Aircraft, the famed light-sport aircraft marque and maker of the perennially popular RV6/6A, RV7/7A, and numerous additional kit aircraft models, commenced subcontracting the manufacture of select aircraft parts to fabrication concerns utilizing laser cutting processes.

The decision to subcontract parts manufacturing was, according to Van’s: “ … made after completing a formal manufacturing process evaluation and extensive fatigue testing of materials used in the manufacturing process, with the purpose of increasing the production capacity for some parts during a period of high demand.”

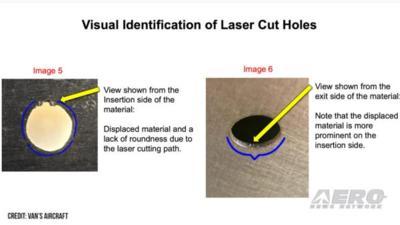

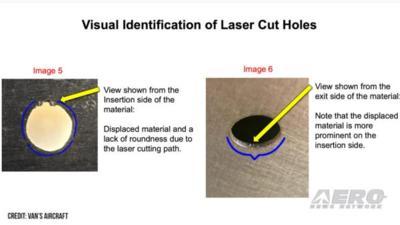

Between February and June 2022, a significant number of Van’s customers reported cracks having formed in parts with laser-cut holes. The company immediately undertook corrective action, conducting testing of cracked parts, assessing the nature of the defects, and devising corrective measures germane to such.

Van’s determined the parts of greatest concern to be:

- Vertical stabilizer, rudder, and elevator spars on all RV-7, RV-8, RV-9, RV-10, and RV-14 empennage/tail kits.

- Horizontal stabilizer spars in RV-7/8 empennage kits.

- Flap and aileron spars shipped early in the laser-cutting process, in RV-7, RV-8, RV-9, RV-10, and RV-14 kits.

Seeking to safeguard its customers and the larger aviation community, Van’s, on 04 July 2023, stated on its website: “We encourage people to pause building of the above specific kits that include laser-cut empennage/tail, aileron, and flap-spar parts. We will be replacing these components and providing further guidance. Even though testing of these specific parts is not yet complete, Van’s is erring on the side of caution by identifying those parts now and will recommend the replacement of these parts due to the relatively high loads carried by those specific parts. We will communicate directly with all affected customers concerning these parts via email this week, to inform those customers as to what steps should be taken. We are executing an initial run of replacement parts on our punch presses now and will be making additional production runs.”

The statement continued: “Our testing program for this issue is ongoing and focused on reviewing the various hole diameters and material thicknesses/types that were used to produce the laser-cut parts. These variables, as well as variations in manufacturing process parameters, can result in a marked difference in the potential for a crack to form in a given hole. We will prioritize testing and manufacturing of replacement parts based on these differences. We are also reviewing the metallurgy of the holes at the third-party test lab, in order to better understand the origin and cause of the observed cracks. From that, we will gain a greater understanding about these cracks and at what stages in the process they are formed (when cut, when dimpled, when riveted). We expect to receive those results soon, even before the full spectrum of overall testing is completed, and we will communicate that information when available.”

Updates pertaining to Van’s investigation of the defective parts and the results and solutions occasioned thereby were posted to the plane-maker’s website on 09 July, 12 July, 15 July, 21 July, 12 August, 10 August, 06 September, and 15 September 2023.

Airborne 05.10.24: Icon Auction, Drunk MedEvac Pilot, Bell ALFA

Airborne 05.10.24: Icon Auction, Drunk MedEvac Pilot, Bell ALFA ANN's Daily Aero-Term (05.13.24): ILS PRM Approach

ANN's Daily Aero-Term (05.13.24): ILS PRM Approach ANN's Daily Aero-Linx (05.13.24)

ANN's Daily Aero-Linx (05.13.24) Airborne-NextGen 05.07.24: AI-Piloted F-16, AgEagle, 1st 2 WorldView Sats

Airborne-NextGen 05.07.24: AI-Piloted F-16, AgEagle, 1st 2 WorldView Sats Airborne 05.08.24: Denali Update, Dad-Daughter Gyro, Lake SAIB

Airborne 05.08.24: Denali Update, Dad-Daughter Gyro, Lake SAIB