Former Boeing Quality Inspector Found Dead In Between Depositions

A Boeing whistleblower was found dead in the midst of a case with Boeing, rousing no shortage of suspicion for the embattled manufacturer.

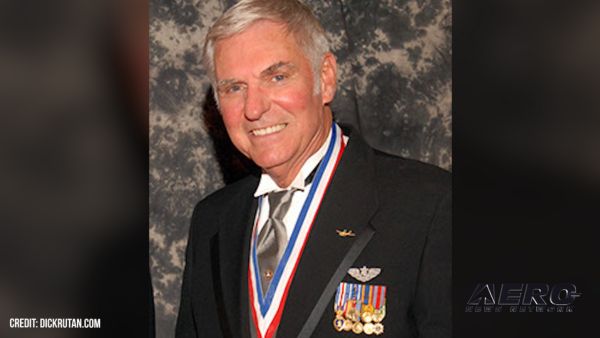

The man, John Barnett, was 62 at the time of death, and died of an apparently self-inflicted wound. He was found in his truck, parked in the lot of the hotel he was staying at. It piqued eyebrows, given the circumstances surrounding his recent whistleblower case. Rumor states that Barnett was at the hotel as part of his testimony against the company, in Charleston, South Carolina. Barnett died in between formal depositions relating to the case against Boeing, having completed his cross-examination by counsel in the case.

Barnett was with the company for more than 30 years, spending time as a quality assurance inspector. In an interview with TMZ, Barnett came across as a cogent, healthy man. In that interview, he pulled back the curtain on the extent of paper pushing that's been happening behind the scenes at Boeing and Spirit Aerosystems. It's hard not to accept his testimony at face value, given the apparent stream of never-ending quality issues that has plagued late-model Boeing products for years now.

"First of all, it's not a 737 problem, it's a Boeing problem," Barnett said, responding to a question about the then-new issue surrounding the MAX 10 door plug failure. "I know the FAA's gone in and done due diligence and inspections, to assure that the door plugs on the '37 are installed properly, and the fasteners are on properly. My concern is, what's the condition of the rest of the airplane? And the reason my concern for that is, back in 2012, Boeing started removing inspection operations off their jobs. So it left the mechanics to buy off their own work. So what we're seeing with the door plug blowout is what I've seen with the rest of the airplane as far as jobs not being completed properly, inspections, steps, being removed, issues being ignored. My concerns are with the 737 and 787, because those programs have really embraced the theory that quality is 'overhead' and non value-added. So those two programs have really put a strong effort into removing quality from the process."

Barnett continued, speaking on the difficult relationship between QC inspectors and two companies that want them to find as little as possible, no matter the method.

"When I first started working in Charleston, I was in charge of pushing back defects to our suppliers, and what that meant was I'd take a group of inspectors and actually go to the supplier and inspect their product before they sent it in. Well I'd taken a team of four inspectors to Spirit Aerosystems to inspect the 41 section before they sent it to Charleston.. and we found 300 defects, some of them were significant that needing engineering intervention. When I returned to Charleston my Senior Manager told me we had found too many defects, and he was going to take the next trip. So the next trip he went on he took two of my inspectors, and when they got back they were given accolades for only finding 50 defects. So I pulled that inspector aside and said "Did Spirit really clean up their act that quick? That don't sound right." And she was mad, she said "no, the two inspectors were given two hours to inspect the whole 41 section and then kicked off".

One of Barnett's predictions on Boeing quality said that he expected as many as a quarter of the passenger O2 systems in the average aircraft could be nonfunctional in an emergency. He found that some oxygen bottles were not discharging as intended, when inspecting systems to decommission. He arranged for a bench test and investigation to be done by the company's in-house personnel, which checked the functionality of 300 systems as they would be used in an in-flight emergency. The results were bleak, with 75 of the brand-new O2 systems failing to deploy as intended. Barnett said that his findings and concerns were largely ignored, with the FAA telling him that Boeing reported it was already at work on the issue. Boeing later blamed it on defective O2 bottles from their supplier, and essentially promised that none of the affected units had been installed on production aircraft.

ANN's Daily Aero-Term (05.09.24): Hold Procedure

ANN's Daily Aero-Term (05.09.24): Hold Procedure ANN's Daily Aero-Term (05.06.24): Altitude Readout

ANN's Daily Aero-Term (05.06.24): Altitude Readout ANN's Daily Aero-Linx (05.06.24)

ANN's Daily Aero-Linx (05.06.24) Airborne-NextGen 05.07.24: AI-Piloted F-16, AgEagle, 1st 2 WorldView Sats

Airborne-NextGen 05.07.24: AI-Piloted F-16, AgEagle, 1st 2 WorldView Sats Aero-News: Quote of the Day (05.07.24)

Aero-News: Quote of the Day (05.07.24)