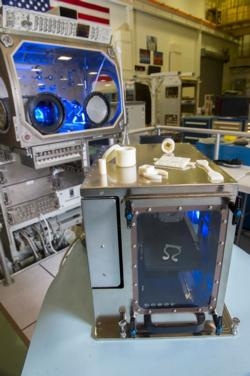

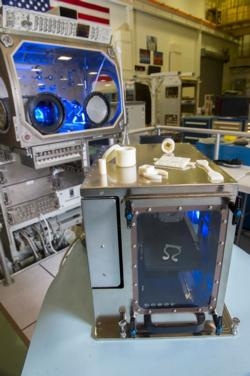

Device Developed By Made In Space To Be Installed Aboard ISS

In the not-too-distant future, some parts and tools intended to be used in space will be fabricated in space, rather than produced on the ground and shipped to orbit.

The first 3D printer intended for in-space use was set to depart aboard a rocket from Cape Canaveral, FL, headed for the International Space Station (ISS) early Saturday morning.

This “machine shop for space” will mark the first time that a multi-purpose manufacturing device will be utilized off-world to create parts, tools and emergency solutions. Developed by Made In Space, Inc., under a contract with NASA Marshall Space Flight Center (MSFC), the 3D printer is part of a technology demonstration intended to show that on-site, on-demand manufacturing is a viable alternative to launching items from Earth.

“Everything that has ever been built for space has been built on the ground. Tremendous amounts of money and time have been spent to place even the simplest of items in space to aid exploration and development,” said Aaron Kemmer, Chief Executive Officer of Made In Space. “This new capability will fundamentally change how the supply and development of space missions is looked at.”

Following delivery to ISS, the 3D printer is scheduled to be installed in the Microgravity Science Glovebox (MSG) to conduct its series of prints. The printer will create a series of test coupons, parts, tools, use case examples and even STEM project designs by students as part of the 3D Printing in Zero-G Experiment. This experiment, intended to demonstrate additive manufacturing capabilities in space, was developed through a partnership between Made In Space and NASA MSFC. Made In Space is working with business partners to formulate additional use case examples to demonstrate printer capabilities.

Made In Space’s additive manufacturing technology creates 3D objects layer by layer from filament through an extrusion method specifically adapted for the challenges of the space environment. In addition to designing and building the hardware, Made In Space will be operating the printer from a mission control ground station.

“There were dozens of specific problems we had to solve in constructing a 3D printer for the Space Station. From thermal process adjustments to rigorous safety requirements, the challenges our team had to overcome were numerous, and we’re deeply proud to see the results of the work done by the Made In Space and NASA MSFC team now head out for a grand field test,” said Kemmer.

This first printer will be using ABS plastic while the second generation unit, scheduled for delivery to ISS in 2015, will offer multiple material capacity and an increased build volume. The second Made In Space printer will be available for use by businesses, researchers and anyone who wants to create in-space hardware rapidly, affordably, and safely.

“Placing additive manufacturing in space will lead to similar capabilities on every future space station, deep space exploration vehicle, and space colony,” said Kemmer. “Rapid construction of important materials is a critical need if humans are going to establish a greater footprint in our universe.”

Made In Space developed the zero-gravity printer through NASA’s Small Business Innovation Research (SBIR) program. The prototype unit was tested on Zero-G Corporation’s modified Boeing 727 parabolic airplane, made possible by NASA’s Flight Opportunities Program. The flight unit passed NASA’s extensive safety and operational standards on the way to being deemed flight ready.

“This is more than a 3D printer," Kemmer said. 'It’s more than a machine shop in space. It’s a landmark for humanity. For the first time in the history of our species, we will be manufacturing tools and hardware away from the Earth. Now that we’ve made this breakthrough, the sky is no longer the limit for additive manufacturing – the era of off-world manufacturing has begun.”

Airbus Racer Helicopter Demonstrator First Flight Part of Clean Sky 2 Initiative

Airbus Racer Helicopter Demonstrator First Flight Part of Clean Sky 2 Initiative Diamond's Electric DA40 Finds Fans at Dübendorf

Diamond's Electric DA40 Finds Fans at Dübendorf ANN's Daily Aero-Term (04.23.24): Line Up And Wait (LUAW)

ANN's Daily Aero-Term (04.23.24): Line Up And Wait (LUAW) NTSB Final Report: Extra Flugzeugbau GMBH EA300/L

NTSB Final Report: Extra Flugzeugbau GMBH EA300/L Classic Aero-TV: 'Never Give Up' - Advice From Two of FedEx's Female Captains

Classic Aero-TV: 'Never Give Up' - Advice From Two of FedEx's Female Captains