Sat, Jun 10, 2023

McFarlane Acquires Airforms

Founded in 1971, Baldwin City, Kansas-based McFarlane is a diversified manufacturing company specializing in the production of affordable, high-quality FAA-PMA (Parts Manufacture Approval) components. McFarlane’s catalog comprises parts for general aviation, commercial, experimental, homebuilt, and Light-Sport Aircraft (LSA) models.

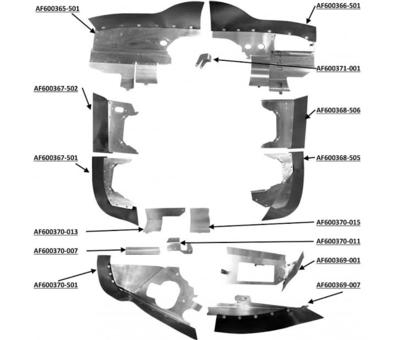

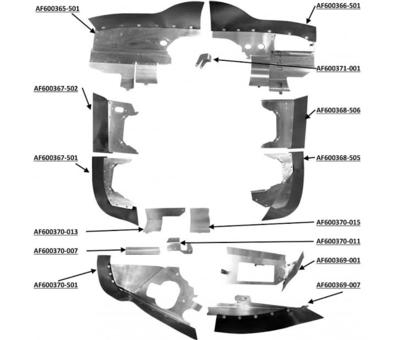

On 07 June 2023, McFarlane subsidiary Airforms introduced a new series of FAA-PMA engine baffles compatible with all Cessna-152 OEM configurations.

Designed as replacements for aging factory installations, Airforms’s new baffles have undergone individual PMA approval and may be purchased as standalone units or as a complete set. The product’s reinforced design ensures extended durability and reduces metal fatigue failures. What’s more, Airforms’s baffle assemblies are offered in both a bare metal and a corrosion-resistant powder-coated finish. Standard silicone seals and low friction COWL SAVER seals are available as options.

Airforms’s manufacturing operations are based at the company’s Wasilla, Alaska Airforms Center for Engine Baffle Excellence.

Baffles are essential to the business of routing cooling air around air-cooled aero-engines—such as the Lycoming O-235-L2C powerplant common to Cessna’s storied 152 aircraft family. Broadly speaking, air-cooled general aviation engines are cooled primarily by a process known as pressure cooling—the rudiments of which constitute surrounding the engine with a cowling and utilizing a system of baffles to seal and direct ram-air around the powerplant. The described architecture occasions high-pressure (relative to ambient atmospheric pressure) which forces air to flow between the heat-radiating fins typical of the cylinder-assemblies of air-cooled engines. Many higher-performance aircraft designs make use of cowl-flaps which, when opened by the pilot, reduce air-pressure below the engine, thereby inducing greater air-flow (high-pressure to low-pressure) through such.

McFarlane holds design approval and FAA-PMA for over 2,700 discrete replacement parts for numerous aircraft makes.

More News

With Testing Soon Complete, Launch Preparations Begin in Earnest Sierra Space's Dream Chaser has been put through the wringer at NASA's Glenn Armstrong Test Facility in Ohio, but w>[...]

Takeoff Roll The process whereby an aircraft is aligned with the runway centerline and the aircraft is moving with the intent to take off. For helicopters, this pertains to the act>[...]

“We’re proud of the hard work that went into receiving this validation, and it will be a welcome relief to our customers in the European Union. We couldn’t be mor>[...]

"Aircraft Spruce is pleased to announce the acquisition of the parts distribution operations of Wag-Aero. Wag-Aero was founded in the 1960’s by Dick and Bobbie Wagner in the >[...]

IDENT Feature The special feature in the Air Traffic Control Radar Beacon System (ATCRBS) equipment. It is used to immediately distinguish one displayed beacon target from other be>[...]

Sierra Space Repositions Dream Chaser for First Mission

Sierra Space Repositions Dream Chaser for First Mission ANN's Daily Aero-Term (05.10.24): Takeoff Roll

ANN's Daily Aero-Term (05.10.24): Takeoff Roll Aero-News: Quote of the Day (05.10.24)

Aero-News: Quote of the Day (05.10.24) Aero-News: Quote of the Day (05.11.24)

Aero-News: Quote of the Day (05.11.24) ANN's Daily Aero-Term (05.11.24): IDENT Feature

ANN's Daily Aero-Term (05.11.24): IDENT Feature