Mon, Sep 10, 2012

Aircraft With No Leading-Edge Slats Will Be Quieter And More Environment-Friendly

In a effort to make air travel quieter and more environment-friendly, researchers at the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR), together with partners Airbus, EADS Innovation Works and Cassidian Air Systems, have been carrying out research to reduce the aerodynamic drag of aircraft. A recent result of that research is the development an alternative to the traditional leading-edge slat.

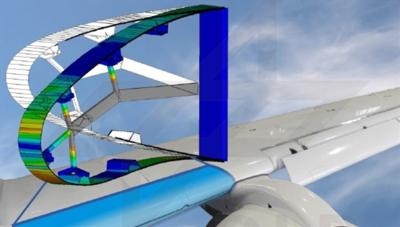

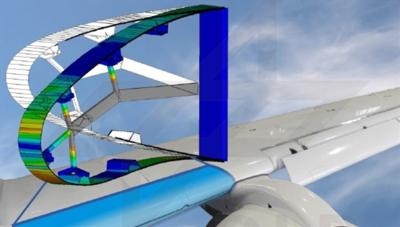

A morphing leading edge is expected to replace slats to create an innovative high-lift system. The testing data shows that the configuration should significantly reduce drag and noise during landing. Tests were carried out between August 27 and September 7 in one of Europe's largest wind tunnels at the Russian Central Aerohydrodynamics Institute’s (TsAGI) Zhukovsky research facility south of Moscow.

In the wind tunnel, the system's operation and performance were tested under realistic conditions. "The measurements on the droop nose here at TsAGI are just one example of the exceptional collaboration between DLR and TsAGI. We are looking forward to future cooperation," said Sergey L. Chernyshev, Executive Director of TsAGI. Normally, the flaps on the trailing edges of the wings and the slats located on the leading edges are extended during take-off and landing to provide the necessary lift at low speeds. There is a gap between the wings and the slats, through which air can flow from the underside of the wing to the top – generating noise. With the development of the smart droop nose, a morphing wing leading edge, the researchers have solved this problem. "The smart droop nose morphs itself during take-off and landing in such a way that no separate slats are necessary. The leading edge can be lowered by up to 20 degrees with virtually no loss of lift," explains DLR project leader Markus Kintscher

from the DLR Institute of Composite Structures and Adaptive Systems in Braunschweig.

The researchers also want to minimize drag to reduce fuel consumption. To accomplish this, the wing surfaces have been made as flat as possible to achieve laminar airflow. This reduces the air resistance by up to 12 percent. "The particular challenge in this project was to unite conflicting requirements," explains DLR Department Head Hans-Peter Monner. "On the one hand, the structure needs to be very elastic, to enable it to morph to the required shapes, but on the other it has to be very rigid. Ultimately, the leading edge must bear around one third of the weight of the aircraft during landing." A suitable material was required to ensure that the leading edge of the wing is not too heavy. During their experiments, the researchers concentrated on the glass- and carbon-fiber reinforced composites that are typically used in the aviation industry. A glass-fiber reinforced material turned out to be the most suitable for meeting the requirements.

In the concept of the droop nose, the skin on the front edge of the wing is just curved, not stretched. This stresses the material as little as possible. The scientists position individual layers one on top of the other, in such a way that the skin creates a structure that has a customised rigidity distribution. The leading edge morphs into the desired shape via integrated actuators and support elements along the wingspan, thus achieving very high stability. Soon, the new wing leading edge will be further developed to meet industrial requirements such as lightning protection, de-icing and the ability to withstand bird strikes.

(Image provided by DLR)

More News

Inversion to Launch Reentry Vehicle Demonstrator Aboard SpaceX Falcon 9 This fall, the aerospace startup Inversion is set to launch its Ray reentry demonstrator capsule aboard Spac>[...]

"We are excited to accelerate the adoption of electric aviation technology and further our journey towards a sustainable future. The agreement with magniX underscores our commitmen>[...]

"The journey to this achievement started nearly a decade ago when a freshly commissioned Gentry, driven by a fascination with new technologies and a desire to contribute significan>[...]

Aero Linx: OX5 Aviation Pioneers Each year a national reunion of OX5 Aviation Pioneers is hosted by one of the Wings in the organization. The reunions attract much attention as man>[...]

"Our driven and innovative team of military and civilian Airmen delivers combat power daily, ensuring our nation is ready today and tomorrow." Source: General Duke Richardson, AFMC>[...]

SpaceX to Launch Inversion RAY Reentry Vehicle in Fall

SpaceX to Launch Inversion RAY Reentry Vehicle in Fall Aero-News: Quote of the Day (04.23.24)

Aero-News: Quote of the Day (04.23.24) Aero-News: Quote of the Day (04.20.24)

Aero-News: Quote of the Day (04.20.24) ANN's Daily Aero-Linx (04.20.24)

ANN's Daily Aero-Linx (04.20.24) Aero-News: Quote of the Day (04.21.24)

Aero-News: Quote of the Day (04.21.24)